Na koncie mamy tysiące naprawionych maszyn — a ta liczba codziennie rośnie. Każdego dnia nasi specjaliści lokalizują usterki i się ich pozbywają. Sprawdź opinie naszych klientów i zobacz, z kim mieliśmy okazję współpracować oraz jakie certyfikaty otrzymaliśmy.

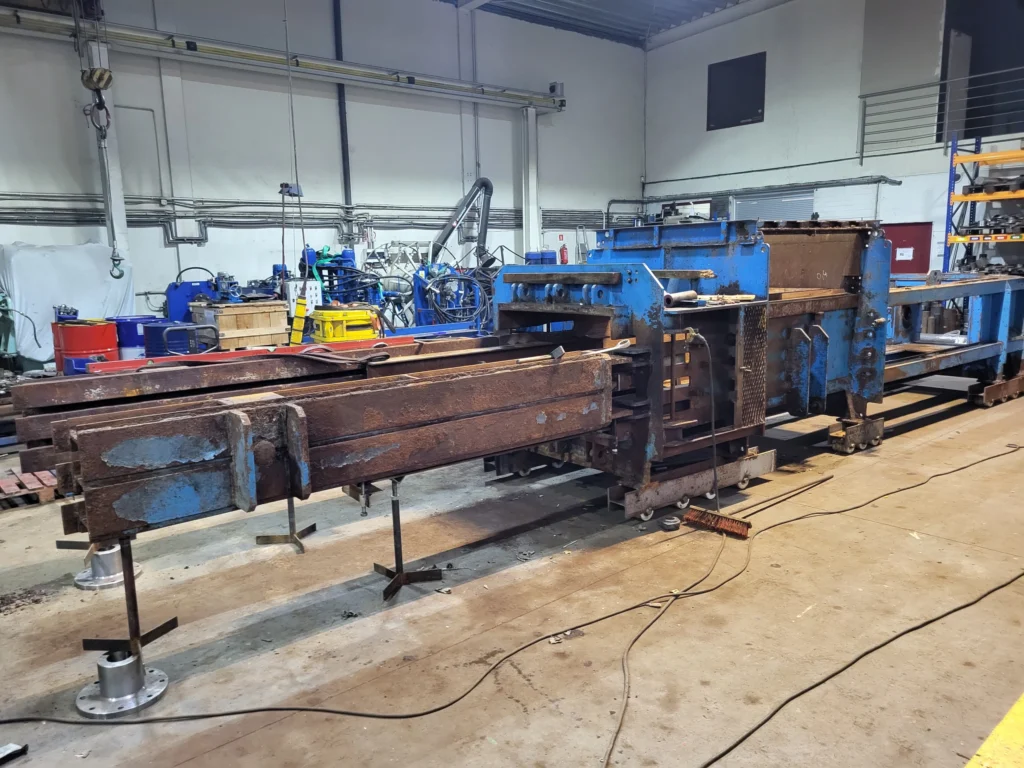

Overhaul of ANIS ATS 110-75-130-4HT Baling Press with Perfolux 1300 Perforator

Overhaul of ANIS ATS 110-75-130-4HT Baling Press with Perfolux 1300 Perforator

Land-based industry project

Scope of the project:

A comprehensive overhaul and full restoration to working order of the ANIS ATS 110-75-130-4HT baling press with integrated Perfolux 1300 perforator, following a long period of inactivity. The project included complete diagnostics, disassembly, reporting, refurbishment, and adaptation of the equipment to the client’s new operating environment.

Works performed:

-

- Documentation

Identification and photographic documentation of individual components in their initial condition. - Inspection and diagnostics

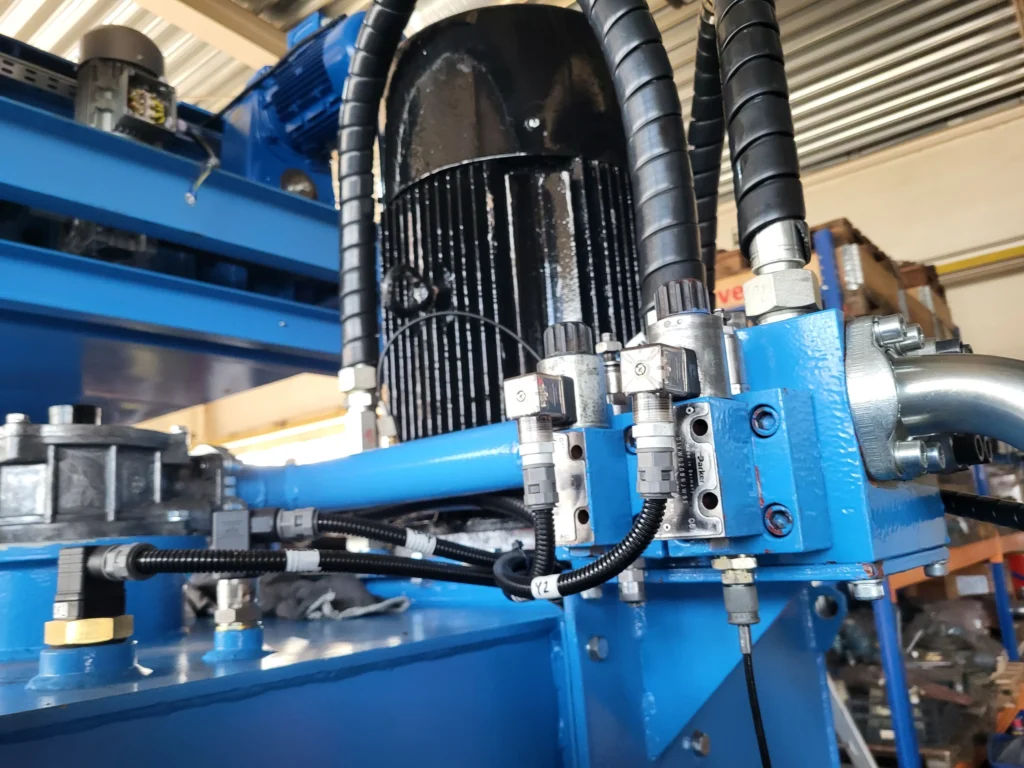

- Disassembly of hydraulic components, including: 8 hydraulic cylinders, 2 pumps, valve blocks, motor, oil cooler, filter unit, and hydraulic tank.

- Disassembly of mechanical subsystems of the press, including:

– moving elements of the compaction channel, strapping arms, plunger and wire lances (including chain drive),

– wire guides, rollers, feed hopper assembly, base frame,

– perforator blades and drive system (worm and bevel gear units). - Detailed inspection of the electrical system and automation components.

- Inspection of end-position and proximity sensors.

- Assessment of electrical panels and control systems.

- Preparation of a comprehensive verification report as a basis for further work.

- Modernisation and overhaul

-

Refurbishment of the electrical switchgear for the press and perforator:

– Delivery and installation of new automation components: push buttons, signal lights, and emergency stop switches.

– Replacement of cable trays, protective conduits, and UV-resistant control cables.

– Design, fabrication, and installation of 4 new electrical junction boxes.

– Supply of cable terminals and completion of missing wire markings. -

Overhaul of electric motors:

– 30 kW main motor for the hydraulic pump unit,

– 2 × 3 kW and 1 × 0.18 kW perforator motors. -

Major refurbishment of mechanical and hydraulic components:

– Regeneration of piston rods and cylinders

– Replacement of bushings, pins, lugs, and guide rollers.

– Hinge alignment.

– Complete delivery of all necessary spare parts.

-

-

Adaptation of the machine’s base frame to the client’s new site layout and operating conditions.

- Documentation